|

|

|

|

|

Photoluminescent Products |

|

|

|

|

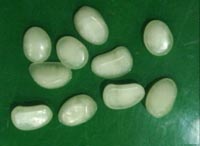

Photoluminescent Stone

key words: Glow in the dark stone, glow

rock, glowing pebble,luminous gravel, glow rubble

|

| |

Photoluminescent stone is a new style glow in the dark products which is made from the synthetic resin

or glass related materials with photo luminescent

pigments. After absorbed the daylight or lamplight for 10—20 minutes, it can glow in the dark for about

10 hours with the yellow-green , blue-green, sky blue etc. colour. It is a non-radioactive, non-toxic and environmental-protective products.

With the beautiful decorative glow effect and safety direction function, glow stone is suitable for many application area. It can be used in footpaths, gardens, rockeries, pebble paths, terrazzo concrete, driveways and so on. Spreading around the swimming poor, puting in the aquarium or inlay into the scenery wall all are the good idea for us to decorate the new house.

Welcome to contact us! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

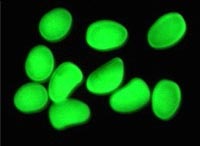

Photoluminescent

stone , also known as artificial luminous pebble or rubble, is the use of

rare earth elements activated alkaline earth aluminate , silicate and

other high-tech self-luminous products, natural stone because it contains

large amounts of luminous radiation can not be used in home decoration and

other fields.

Companies

use the new light-induced photoluminescent material itself features,

combined with the latest production technology of artificial jade out of

the rubble with luminous hardness and appearance characteristics of

natural stone , and there is no radioactive hazard of natural stone

products are widely applied indoor and outdoor decoration , landscape

design and other fields, its novelty luminous effect , not only beautify

the environment , the landscape dotted and off , more nights instructions

and labeled functional, and therefore the majority of domestic and foreign

customers .

Outstanding

features luminous gravel are:

Absorb

visible light during the day and 10 to 20 minutes, you can continue to

glow in the dark more than 12 hours , the glowing brightness and duration

is 30 to 50 times that of traditional ZnS luminous material , and

unlimited recycling , non-radioactive, nontoxic to humans .

Glow in the dark stone

and rubble is my company

developed a new type of interior decoration materials , resin or glass raw

materials as the main ingredient to join the special luminous Process

After forming, shaping and molding natural , can be crushed after doing

other ingredients used , the minimum diameter for milli , can be used for

road styling , art concept reflects , grooming guidelines. Transformation

due to the small particle size can be relatively simple shape , modern

styling and grooming guidelines artistic quality materials .

Features:

STORING

low excitation conditions , high luminance long duration. High temperature

resistance and good electrical insulation properties. Strength , hardness,

corrosion resistance, good chemical stability ; optical properties,

friction , wear resistance and damping performance muffler . Environmental

, safety, quality of light . Plasticity, shape changes, easy molding .

Recyclable rate, strengthen environmental awareness is increasingly

recognized.

|

|

Photoluminescent

pigment and polyvinyl chloride resin formulation

Polyvinyl chloride (PVC) 16-18% plus ring has 0%, hot melt after as puree. Wataru first ring B into the container, then add PVC. And with the added with partners. Upon completion of the addition, this container does not exceed 50 ℃ in hot water and dissolved with stirring 15 minutes, until the PVC fully dissolved, which is puree puree Photoluminescent pigment30% plus 100% stir for 30 minutes Become a luminous plasma, the other plus glow in dark powder varnish or glue the end of the 107 plus luminous glow powders can be prepared with the use of different pulp.

Photoluminescent pigment and unsaturated polyester resin formulations

The first time the estimated amount of product produced 191 prospective amount of resin cups into the container, then add 191 resin, 20 parts per 100 parts glow in dark powder, stir together 2-4 parts hardener, stir well, add 1-2 parts of accelerator, sufficiently stirred, the above procedure can not be reversed formulated.

Several questions When dissolved in indirect puree with warm water, hot water does not exceed the maximum temperature of 65 ℃, the minimum can not be less than 48C.

PVC construction materials in the winter may be appropriate to give a little to make it thickens some, the summer construction should be appropriate cyclohexanone Cadogan some thinning otherwise make poor scraping

The above formulation has a poor quality of raw material problems, such as when a large amount of work, with a good first luminous paste, once a trial to identify the optimal ratio of raw materials to achieve the best results.

Use unsaturated resin Precautions

① construction temperature, the ambient temperature is not lower than that during construction of 15 ℃, air relative humidity should be less than 80%.

② The maximum amount of the curing agent is not more than 6%, the minimum amount of water is less than 0.5% accelerator.

③ mediation resin curing rate is generally only the amount of change in the accelerator.

④ Available styrene resin viscosity is too diluted when

⑤ the 1st hardener must be used on the 1st accelerator, the 2nd with the 2nd curing agent accelerator must not be misused.

You can not use the curing agent and accelerator simultaneously added to the resin, a mixture of both or near prohibited place.

⑥ not fitted with bronze resin, phenolic resin powder and never got into sulfuric acid, rubber, copper, methanol and other objects, in particular water and water vapor in the bottom frame, otherwise it will affect the performance of resin and finished finish.

⑦ resins and solid, promoting two lines flammable, use, storage, transport should be careful. Should be stored in a cool place, not near the fire, nor the mouth spacious store.

⑧ tool can take care of themselves in front of the uncured resin, sawdust with warm water, add detergent wash, some molds or tools

|

|

|